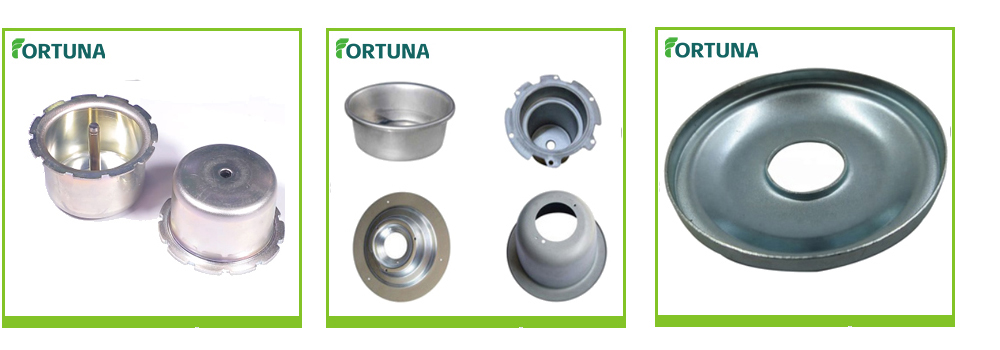

The Deep Drawn Metal Stamping

The stamping process is considered deep drawn stamping or deep draw, when a part is pulled(drawn) into a die cavity and the depth of the recess equals or exceeds the minimum part width. Deep drawing uses radial tension-tangential compression to shape the metal.

This process transforms flat sheet metal, or blank, into a hollow vessel that may be cylindrical or box-shaped, with straight or tapered sides or a combination of straight, tapered and curved sides.

Deep Draw Stamping Modifications

This from of stamping usually involves other forming operations to complete the part such as: beads, ribs and flanges.

Bulging: the process of expanding the walls of a cup, shell or tube with an internally expanding segmental punch or a punch composed of air, liquids, semi-liquids or of rubber and other elastomers; this expansion may be symmetrical or non-symmetrical.

Coining: a closed -die squeezing operation in which all surfaces of the work are con fined or restrained.

Curling: forming an rolled edge at the open end of a part.

Dimpling: localized indent forming, so as to permit the head of rivet or a bolt to fasten down flush with the surface of the metal.

Embossing: a process that produces relatively shallow indentations or raised designs with no significant change in metal thickness.

Extruding: a process that produces relatively shallow indentations or raised designs with no significant change in metal thickness.

Holes: a shaped portion of metal is cut from the drawn part using conventional, extruding, or piercing punches.

Ironing: operation in which the thickness of the shell wall is reduced and its surface smoothed.

Deep Draw Stamping Process

Step1: Determine Scope

Step2: Cutting Blanks

Step3: Starting Cup

Step 4: Keep Drawing

Step 5: Custom features: We produces custom deep draw parts for our customers, including a variety of features:

*Beading

*Burnishing

*Chamfering

*Coining

*Embossing

*Flange forming

*Ironing

*Marking

*Multiple side piercing

*Shaped flange trimming and so on

Deep Draw Stamping Materials:

Deep Draw stamping offers many advantages including lower costs for high volume production and the ability to create parts with a high strength-to-weight ratio. It’s an ideal metal forming method of cylindrical parts and components where there is a minimal emphasis on surface marks.

Our deep draw stamping capabilities work with a variety of metals, including:

*Cold rolled Steel

*Stainless steel, 400 series and 300 series

*Aluminum

*Copper/Alloy

*Brass

*Iron and so on.