Well, there are a lot of precision metal stamping companies available out there. It is very difficult to point out one single company because all have their one unique selling point so to speak. However, it is important to understand the kind of reputation a company has in the market.

Four top points to be considered:

1.Quality standard certifications:

One assurance is that a potential supplier is certified to a quality standard, whether it’s IATF (International Automotive Task Force), ISO (International Organization for Standardization), or one of the many medical, military, or aerospace quality standards. Whether your industry requires it or not, if they’ve done the work to achieve and maintain registration to a quality standard, it demonstrates an investment in their organization. But a good vetting process shouldn’t stop there.

2. Industry experience of precision stamping parts manufacturers.

3. Production capacity of precision stamping parts manufacturers.

4. Service coordination.

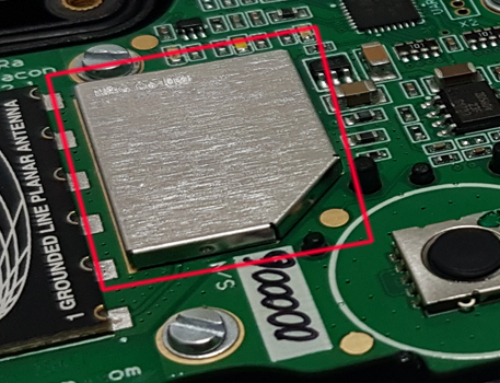

There are thousands of companies across China that offer metal stamping services to deliver components for industries in automotive, aerospace, medical, and other markets.As global markets evolve, there is an escalated need for quickly-produced large quantities of complex parts.Whether the overall service ability from drawing evaluation to proofing to molding to batch delivery can keep up with time, accuracy requirements and quality requirements.

Metal stamping is a fast and cost-effective solution for this large-quantity manufacturing need. Manufacturers who need metal parts stamped for a project generally look for three important qualities:

- High quality /durability

- Low Cost

- Fast turnaround time

Fortuna Metal, over 40 years of intensive focus on precision stamping parts, company culture that takes customer needs as the work result.