The general knowledge of precision metal stamping processing is very much, there are the main measures to reduce the manufacturing cost, according to the total deformation properties of materials, stamping process is divided into two categories, stamping process of five kinds of deformation three aspects:

1.The main way to reduce manufacturing costs.

A. Rationalization levelof progressive process

B. Improve mold design level, reduce working procedure, improve mold life

C. With the automation of progressive stamping process and high speed level, reduce cost

D. Design the mold that each workpiece processes together

E. The utilization method of adopting progress data to decreases cost

2. According to the total deformation properties of the data, precision metal stamping process is divided into two categories:

A. Separation process: under the action of external force, the stress of the deformed part exceeds the strength limit of the data, and the plate breaks and leaves.

B. Plastic deformation process: under the action of external force, the stress of the deformed part of the sheet metal exceeds the yield limit of the data, but does not reach the strength limit, only plastic deformation table is generated to obtain certain shape and scale.

3. Five deformations of precision metal stamping process.

A. Solid pressing: redistributing the volume and carrying the data to change the shape or height of the blank.

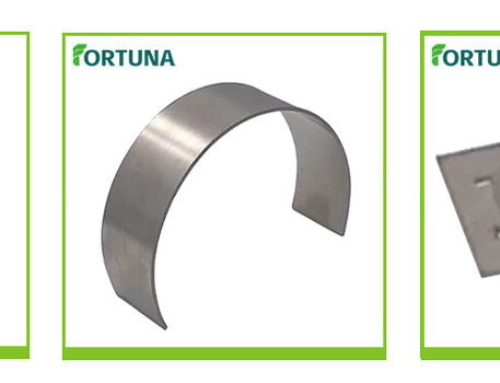

B. Zigzag: change the flat sheet into zigzag parts, and further change the shape of zigzag parts. Bending, curling, distortion, etc.

C. Calendering: stamping a flat blank into a hollow part of the desired shape, or making further changes in the dimensions of the hollow part.

D. Forming: to change the shape of a work piece or blank by means of partial deformation of various properties. There are ups and downs, flanging, necking, bulging, rolling and shaping that are attributed to forming deformation.

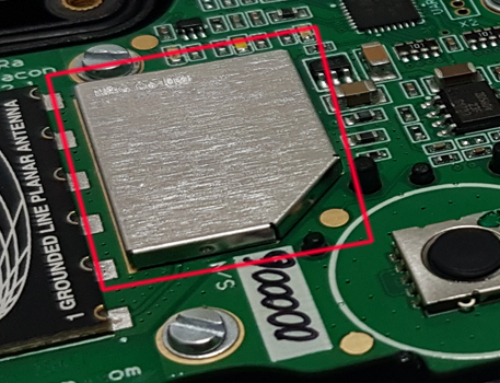

E. Blanking: do not close or close to separate part of the data from another part. There are blanking, punching, edge cutting, blocking, sectioning, incision and so on.

Very good website you have here but I was wondering if you knew of any user

discussion forums that cover the same topics discussed here?

I’d really love to be a part of online community where I

can get opinions from other experienced individuals that share the same interest.

If you have any recommendations, please let me know.

Thanks a lot!

Wow cuz this is excellent work! Congrats and keep it up.

This blog was… how do I say it? Relevant!! Finally I’ve found something which helped me. Many thanks!|

There is definately a great deal to know about this issue. I like all of the points you have made.|

amazing artile

Truly this is a helpful site.

very informative

Hurrah, that’s what I was looking for, what a data!

present here at this website, thanks admin of this web site.

Love the website– very individual pleasant and lots to see!

Nice article

Keep on writing, great job!

Excellent article. I am dealing with a few of these issues as well..|

Hi it’s me, I am also visiting this site regularly, this website is truly pleasant and the viewers are actually sharing pleasant thoughts.|

Very descriptive blog, I loved that a lot. Will there be a part 2?|

Hi there. I discovered your website by way of Google at the same time as looking for a similar topic, your website got here up. It seems great. I have bookmarked it in my google bookmarks to come back then.

Thanks on your marvelous posting! I actually enjoyed reading it, you’re a great author.I will be sure to bookmark your blog and may come back very soon. I want to encourage yourself to continue your great writing, have a nice holiday weekend!

Good way of explaining, and pleasant article to take

information concerning my presentation focus, which

i am going to present in university.

Hiya, I am really glad I’ve found this information. Today bloggers publish only about gossip and internet stuff and this is actually annoying. A good website with exciting content, this is what I need. Thank you for making this web site, and I’ll be visiting again. Do you do newsletters by email?

Hello there, I do think your blog may be having web browser compatibility problems.

When I take a look at your web site in Safari, it looks fine but when opening in Internet Explorer,

it’s got some overlapping issues. I merely wanted to give you a quick heads up!

Aside from that, wonderful blog!

Hi Zane,Thank you.